By Patrick Schmidt

We have all become accustomed to working remotely from a variety of locations. So, it was no surprise to me that I was recently on a conference call with one of my co-workers who was using his time waiting for an oil change and tire rotation at a car dealership to get some work done.

He and I joined the call early and were chatting when he said, “Whoa, there are no new cars out here.” He said that the lot seemed nearly empty and desolate. In a space designed to showcase over 300 new cars, he could count about 60. Where were all the cars?

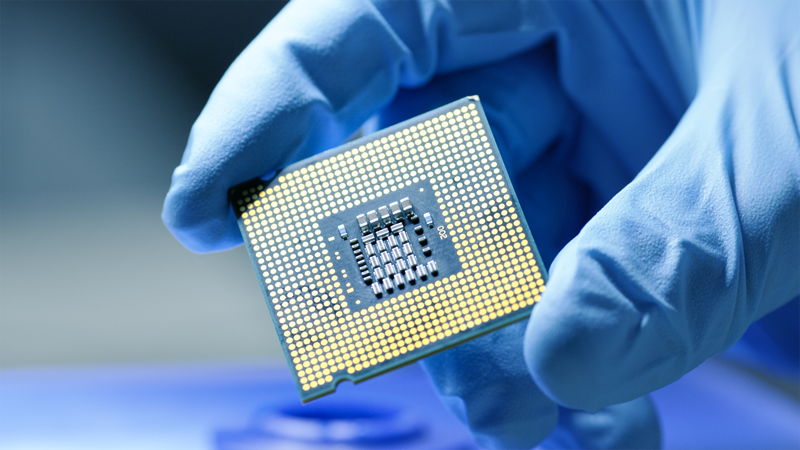

They aren’t there because they can’t be manufactured. We are experiencing a global shortage of semiconductor chips that are used in systems like climate control, onboard navigation, and collision prevention. And it’s not just cars. Everything from appliances to Xbox game consoles are short on the wafers of silicon that make our modern world work.

Where are the chips? Ongoing scarcity is due to the lingering effects from pandemic lockdowns, higher demand from work-from-home scenarios, and a historic drought in the critical chip production hub of Taiwan. So, why don’t we just ramp up production and build some new facilities in other areas? The answer is… it’s complicated.

Building a fabrication facility takes years and costs billions of dollars. Why? One reason is how clean they need to be. Environmental controls to reduce dust particles to 10 per cubic meter for tier 1 production facilities are very costly. As a comparison, the average hospital operating room has around 10,000 dust particles per square meter. Yes, clean rooms need to be that clean.

It also very complex to create each individual chip. For example, it can take more than three months to lay down the billions of transistors necessary for a modern CPU. Intel’s first x86 processor featured 55,000 transistors in 1982. By comparison, AMD’s Epyc Rome processor released in 2020 has 39.54 billion transistors. Epic, indeed.

So, we are past the pandemic and supply is ramping up, right? Not quite. Some industry sources are quoting 52 to 70-week lead times with no clear relief in sight. To that point, Intel CEO Pat Gelsinger noted during a Wall Street Journal interview in April that it could be up to two years before production is able to catch up with demand.

In addition, AMD CEO Dr. Lisa Su revealed in May that the company was being forced to prioritize its higher end processors at the expense of lower-priced chips due to shortages. However, even this shift may not be enough to keep up with the demand.

Delays and shortages like these can foil even the best laid plans. If your organization was planning the rollout of some infrastructure requiring systems with high performance computing hardware, your schedule might be thrown off and deadlines not met. How might you cope with the situation and deliver to your internal customers? I would suggest three ways:

First, you could decide to wait. If supply loosens up earlier, this could be the best course of action. While you wait, it is critical to make sure your service coverages on both hardware and software remain intact in case of an unforeseen outage or other support need. This is waiting, not quitting.

Second, if your project allows for it, you could consider using refurbished technology. Sometimes organizations decide to refresh on a strict schedule. If migrating the technology is not strictly necessary, but only desired or out of habit, going the refurb route could save you time and money.

Third, there could be a cloud option. The initial stages of the COVID-19 pandemic caused many organizations to accelerate their cloud strategy. The ongoing semiconductor chip shortage could as well. Pivoting from on-premises to cloud requires a serious evaluation of each unique situation. However, it could yield a desired future state you hadn’t planned on reaching for years.

In each case, LRS IT Solutions is qualified to help you reach your goals. We offer a variety of OEM and third-party maintenance services, resources for quality refurbished gear, and innovative cloud solutions to meet your needs. For more than 41 years we have guided our clients through their opportunities and challenges. We can do the same for you.

Ironically, I was in the market for a new car when I was talking to my co-worker. Yes, there were few new cars to choose from and I was frustrated. In the end I purchased a certified preowned 2018 sedan with only 15,000 miles on it. How’s that for refurb?

Want to learn more? Fill out the form below and we will connect you with one of our seasoned experts who can help you understand your options.

About the author

Patrick Schmidt is a Technology Lifecycle Management Specialist with LRS IT Solutions. For more than 20 years, he has been helping customers get a firm grasp on their asset and contract management with a combination of comprehensive service level analysis and lifecycle management best practices.